NXT III

The proliferation of multifunction and high-performance electronics has been growing rapidly in areas such as mobile devices and car electronics. However, because these products tend to have short life cycles, production equipment that has the flexibility to respond to ramping up to mass production in a short amount of time and changes in demand is sought after.

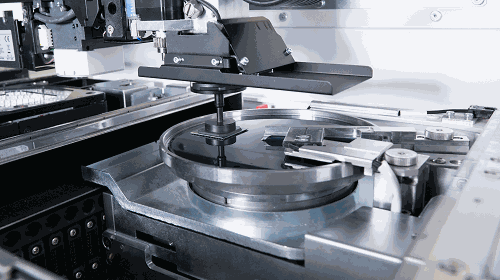

The NXT III is a modular SMT mounter that is able to provide the best line every time for factories that have such kinds of frequent changes for producing electronics devices.

Features

Heads can be exchanged easily

Heads can be exchanged easily without tools.

The heads are lightweight and thus can be removed easily by a machine operator when needing to perform maintenance or troubleshooting when responding to issues.

High speed and high accuracy

Having compact and lightweight heads reduced the load on the machine. As a result, the modules themselves are able to be compact while maintaining high speed and high accuracy.

NXT III special lineup

17% increase in performance

The speed of operations frequently used in actual production has been increased intensively, improving the throughput by 17% compared to previous models.

The M3 IIISE module is effective for module part boards, smartphone boards, and other such panels which have high-density part population

Realtime load control

As parts continue to become even smaller, thinner, and lighter the demand for low-impact placement, in addition to placement accuracy, is also increasing. The combination of the H12L head with the M6 IIIL module makes it possible to control the load during placement in real time. This means that parts can always be placed using the same load regardless of the condition of the panel, preventing damage to parts.

By loading dedicated heads and units into the machine, specific processes such as glue application and flux transfer can be performed inline. This contributes to the reduction of incomplete products and removes the need for investing in dedicated equipment.

SPECIFICATIONS

|

M3 III |

M6 III |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Applicable PCB size (LxW) |

48 x 48 mm to 250 x 510 mm (double conveyor)* |

48 x 48 mm to 534 x 510 mm (double conveyor)* |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Part types |

Up to 20 types of parts (calculated using 8 mm tape) |

Up to 45 types of parts (calculated using 8 mm tape) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

PCB loading time |

For double conveyor: 0 sec (continuous operation) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Placement accuracy |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Productivity |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Supported parts |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Module width |

320 mm |

645 mm |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Machine dimensions |

L: 1295 mm (M3 III x 4, M6 III x 2) / 645 mm (M3 III x 2, M6 III) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

DynaHead(DX) |

||||

|

Nozzle quantity |

12 |

4 |

1 |

|

|

Throughput(cph) |

25,000 |

11,000 |

4,700 |

|

|

Part size |

0402 (01005") to 7.5 x 7.5 |

1608 (0603") |

1608 (0603") |

|

|

Placing accuracy |

+/-0.038 (+/-0.050) mm (3σ) cpk≥1.00* |

+/-0.040 mm (3σ) cpk≥1.00 |

+/-0.030 mm (3σ) cpk≥1.00 |

|

|

Part presence |

o |

x |

o |

|

|

Parts |

Tape |

o |

o |

o |

|

Stick |

x |

o |

o |

|

|

Tray |

x |

o |

o |

|

|

Parts supply system |

|

|

lntelligent feeders |

Support for 4, 8, 12, 16, 24, 32, 44, 56, 72, 88, and 104 mm wide tape |

|

Stick feeders |

4 ≤ Part width ≤ 15 mm (6 ≤ Stick width ≤ 18 mm), 15 ≤ Part width ≤ 32 mm (18 ≤ Stick width ≤ 36 mm) |

|

Trays |

Applicable tray size: 135.9 x 322.6 mm (JEDEC standard) (Tray Unit-M) , 276 x 330 mm (Tray Unit- LT), 143 x 330 mm (Tray Unit-LTC) |

|

Options |

|

Tray feeders, PCU II (Pallet Change Unit), MCU (Module change unit), Engineering panel stand, FUJI CAMX Adapter, Nexim Software |