NPM-X Series

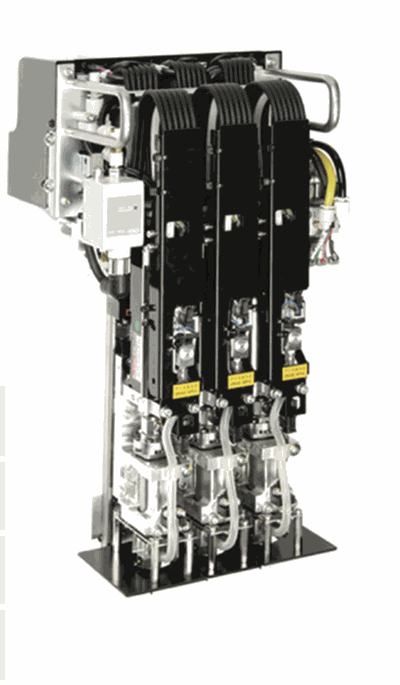

NPM-X Series

Design concept

The NPM-X Series delivers new, innovative technology – combining speed and autonomous controls with single-, dual- and quad-beam motion – into a cost-effective, scalable solution for any manufacturer.

NPM X-Series common attributes

Durable, solid base construction

The NPM X-Series is designed around a stiff frame, constructed of durable materials and built to last. Available in single-, dual- and quad-beam variants.

Linear motor drive system

With onboard dual-drive linear motors complimented by light and rigid beam architecture, the NPM X-Series introduces new industry-leading options; Linear servo motors with dual- drive Y and High Resolution linear scales in each motor.

Versatile head technologies

Unparalleled compatibility means the right placement heads that cater to your specific needs. With faster high voltage motor drives, higher precision Θ architecture and precisely forged stainless steel nozzles and adapters, the NPM X-Series sets new industry standards for handling any mix and any volume.

Versatile-head technology

Flexible mid-speed lightweight 8NH

• 2.3kg lighter with 48V drive system

• Improvement of Θ accuracy via new drive mechanism

|

Speed |

Up to 24, 000 CPH/head |

|

Range |

0402 - 45 x 45 x 12 |

|

Accuracy |

±25 μm (at Max. Speed) |

Versatile-head technology

Component feeders

• Common to all Panasonic pick and place platforms

• Tape feeder supports from 4 to 104mm width and deep pocket to 26mm

• Multi-pitch, multi-width feeders reduce investment

• Self-adjusting with auto teach and splice detection

• Safely hot swap during production

• Auto-load 8mm paper tape feeder

• Single, tri-tube and stackable stick

feeder options

Support station box

•Reduces changeover time with offline cart setup

• Wireless scanner guides operator through setup

• Combine with PanaCIM Material Verification for closed-loop setup

Multi-function transfer unit

• Linear slide with auto reload for successful PoP process

• Supports solder and flux

• Programmable squeegee gap

Gripper

• Pneumatic, adjustable stroke

• Integrated 2D barcode for Nozzle

Anywhere setup

• Compatible with nozzle holder for

on-the-fly changes

Custom nozzles

• Eliminate manual placement with custom vacuum and gripper tools

• Local design expertise with quick

turnaround

• Thousands of special designs

Specifications